The single largest expense on any U.S. dairy farm is the cost of feed. Feed accounts for approximately 50% of the cost of producing a pound of milk. Breaking feed cost down even further, we can see that at current market prices protein (MP) accounts for about 50% of feed cost, with energy (nEL) accounting for about 30%, and forage fiber (eNDF) about 20%. This means that feed ingredient and feed management decisions, particularly around high-protein ingredients, can have huge impacts on the economic efficiencies of a dairy.

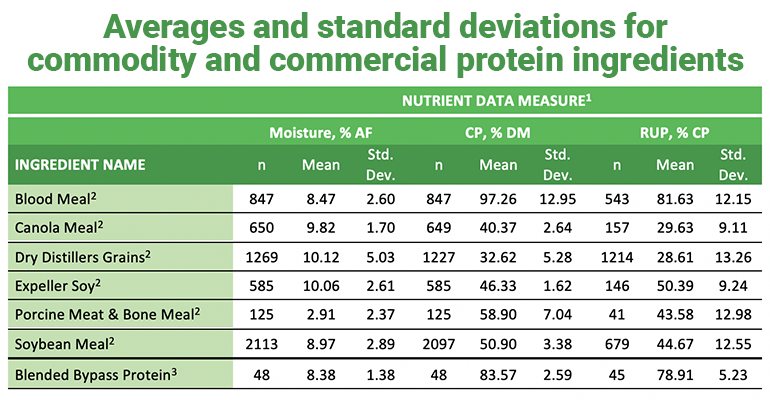

When it comes to feed management, some of the largest areas of opportunity on farm are shrink and nutritional variation of ingredients. Considering variability in feeds, forages are often spotlighted because they vary more than commodities. However, commodities should not be ignored because they too are highly variable and are significant sources of protein and, therefore, cost in a diet. To illustrate, nutrient data summaries on several high-protein ingredients of interest are listed in the table below.

In a normally distributed population, which most ingredients would qualify, approximately 68% of all observations will fall within ± 1 standard deviation of the average. This means that for soybean meal, we would expect 68% of samples to come back between 47.5% and 54.3% crude protein (CP), quite a wide range, when most diets are formulated using 51.5% CP.

Troubleshooting feed variation.

When considering variation in feeds, we typically only concern ourselves with deviation below the desired nutrient value. However, variation above the desired value can be detrimental as well, either in the form of waste or requiring the cow to spend energy dealing with excess. This is particularly the case with protein, which has an energetic cost of synthesizing and excreting excess nitrogen as urea.

Variability in protein-rich feeds can arise from many things including, but not limited to, differences in supplier, crop year, and processing. One way to reduce variation is to eliminate as many of those factors as possible, such as contracting distillers’ grains with a single supplier rather than purchasing from a broker. Keep in mind that there is some inherent variation for all ingredients, even within a single load. So, one of the biggest keys to managing variation is knowing what that variation is. This requires repeated testing and analysis of the protein, moisture, NDF, etc. of commodities, or purchasing from a supplier who does.

The benefits of blended ingredients.

Another relatively easy strategy for managing variation is to use multiple different ingredients. In general, the contribution of any ingredient to the overall variation in the diet changes at a rate equal to the square of its inclusion rate; ingredients that make up a larger portion of the diet contribute more to the variability of the overall diet. Increasing the number of protein ingredients fed should decrease overall diet variability. While all ingredients are variable, from a statistical standpoint, the probability of two ingredients both falling below target is less than for a single ingredient falling below target. With three or four ingredients, the probability is further reduced. This logic is one reason why commercial bypass protein blends are viable options—blending multiple high protein ingredients together reduces the overall variability of the finished product. The consistent quality offered by blended products is demonstrated by comparing the standard deviations between commodity protein ingredients and the commercially blended bypass proteins in the table below.

Reducing or managing ingredient fluctuations allows us to provide a more consistent diet that delivers what cows need, while also reducing the economic and productive costs of overfeeding or underfeeding key nutrients.

1 AF = as fed; CP = crude protein; DM = dry matter; RUP = rumen undegraded protein; n = number; Std. Dev. = standard deviation

2 Data from Rock River Labs, Watertown, WI for all samples classified under each category from 2018-2020.

3 Data from Rock River Labs, Watertown, WI for a commercial bypass protein blend submitted by Papillon from 2018-2020.

Click here to view the original article on Feedstuffs.